ABOUT US

YIXIAO MECHANICAL

Established on September 15th, 2011, Wuxi Yixiao Mechanical Technology Co., Ltd. is a municipal key enterprise that specializes in manufacturing crystallizer-used blank copper tube, crystallizer copper tube and crystallizer assembly, and integrates R&D, design, production and sales as a whole. Located in the hometown of juicy peach at the center of Yangtze River delta, (Zhuji Village, Yangshan Town, Huishan District, Wuxi City), our company enjoys very convenient transportation since it's is adjacent to Shanghai-Nanjing Highway, Shanghai-Yixing Highway, Wuxi-Yixing No. 342 Provincial Highway, and No. 312 National Highway. In addition, with Binhu New City, Taihu Lake Rim Sightseeing Route and Lingshan Buddha dwelling in the south, our company, also boasts a very beautiful and abundant external environment. Thus, we sincerely welcome friends from every walk of life to visit or join us.

Company establishment

registered capital

Total number of employees

Floor Area

Our advantage

Four reasons to choose us.

Quality Management

the company passed the ISO-9001:2008 quality system certification, at the same time was rated as the quality of products in jiangsu province trustworthy enterprises (products), jiangsu province quality, service, integrity aaa grade enterprises...

scientific management

The company adheres to the road of quality and benefit-oriented development, regards quality as the life of the enterprise, regards customers as the God of the enterprise, and cooperates with the technical essence of the industry, pays attention to scientific research and innovation, and continuous product improvement

Service concept

In line with the enterprise policy: high quality and high efficiency, customer first, respect and abide by the contract, according to the needs of users, for customers, with high-quality quality, high-quality service for China to make contributions to the iron and steel power!

Quality Products

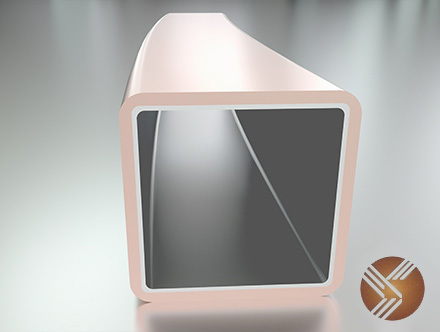

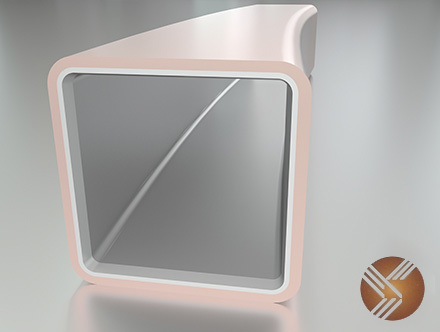

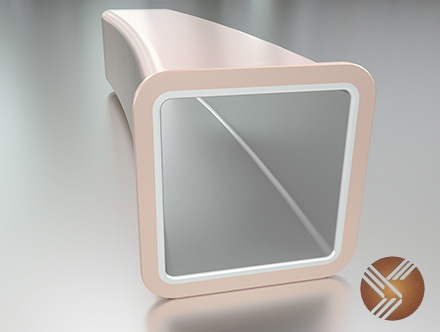

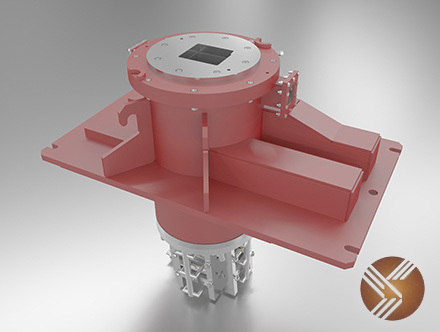

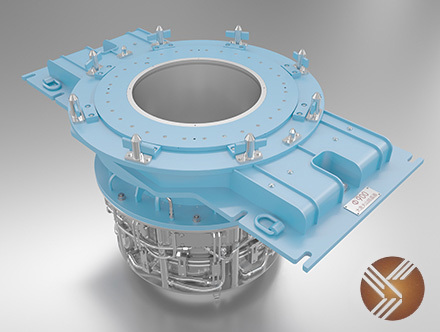

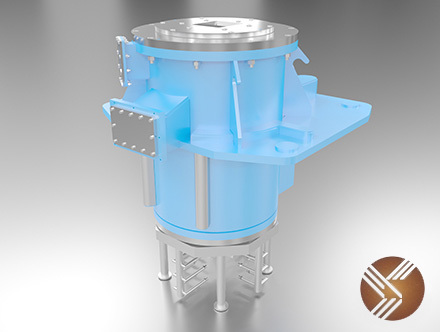

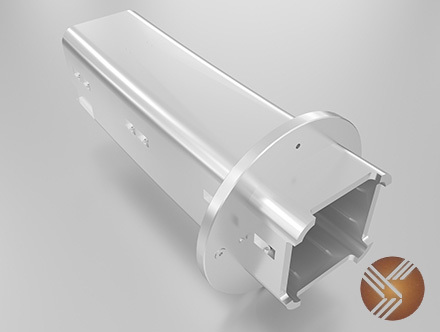

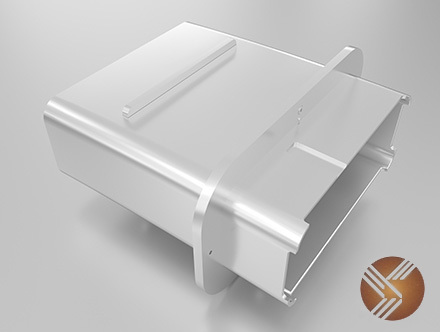

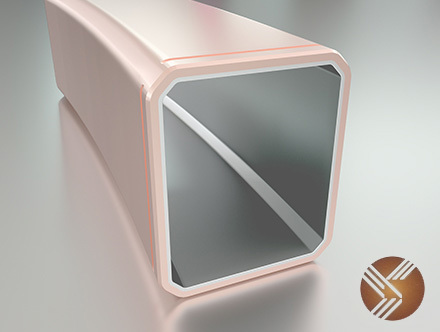

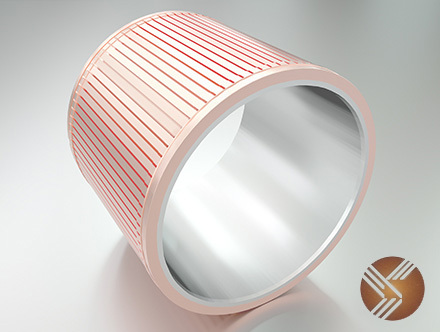

It is a professional manufacturer of blank copper tubes for crystallizers, crystallizer copper tubes and crystallizer assemblies. The crystallizer copper tubes are produced from copper to electroplating.

Product Center

News Center

Committed to providing customers with excellent products and quality after-sales service

2024-03-14

Common sense about the service life of crystal accessories

2024-03-14

The role of continuous casting mold

2024-03-14

What kind of material is used for the copper plate of the crystallizer

Scan Code

YIXIAO MECHANICAL

Add: Zhuji Village Industrial Park, Yangshan Town, Wuxi City, Jiangsu Province.

Tel: 86-510-83950860

Fax: 86-510-83952866

E-mail:200808495@qq.com

Copyright©2023 Wuxi Yixiao Machinery Technology Co., Ltd. Business License